Lorem ipsum dolor sit amet consectetur adipisicing elit. Minima quam aperiam ullam.

(Contact: +8801792223444 for price)

Product descriptions

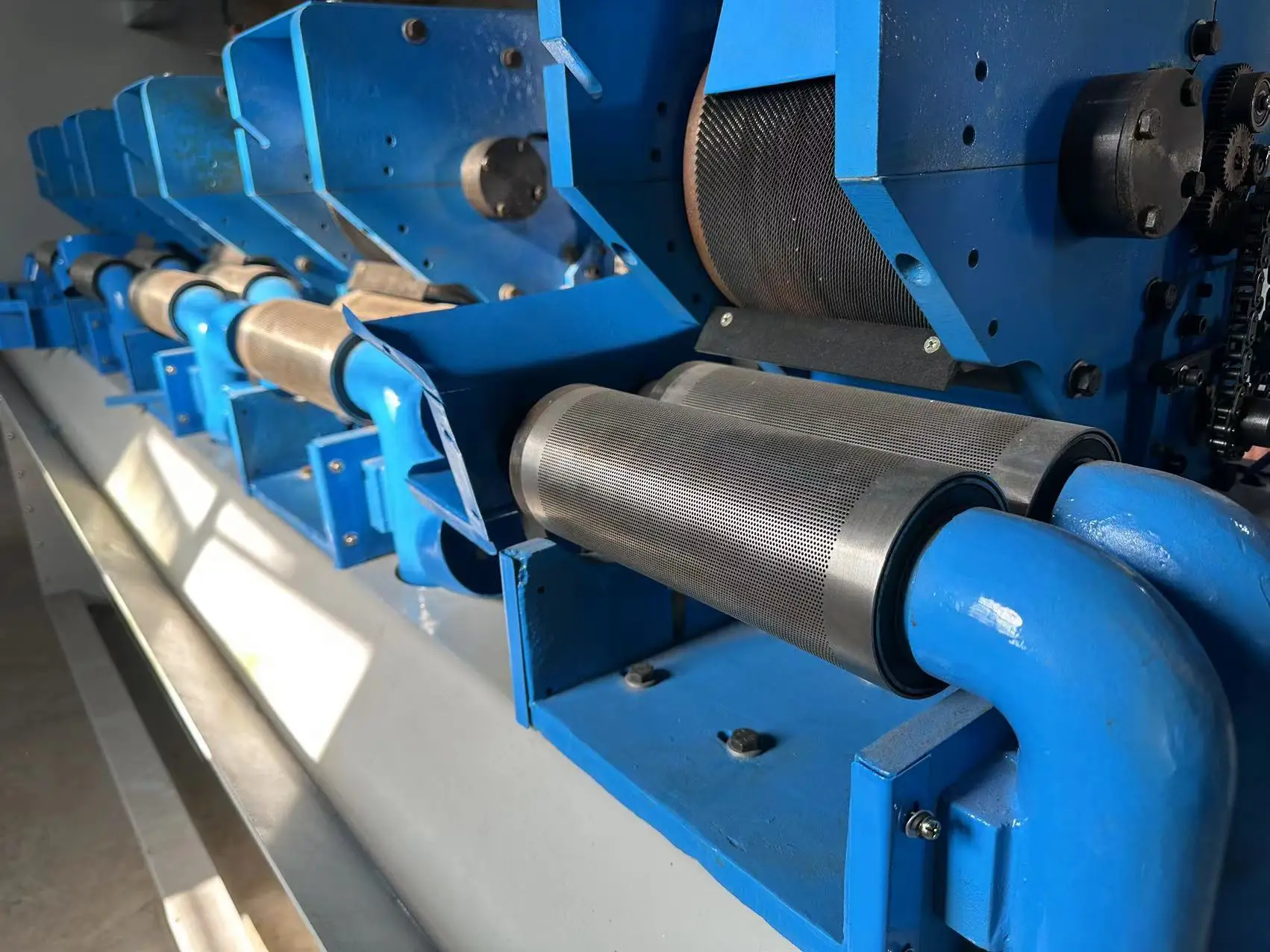

Textile DREF friction spinning machine for spinning core yarn rayon and kevlar yarn

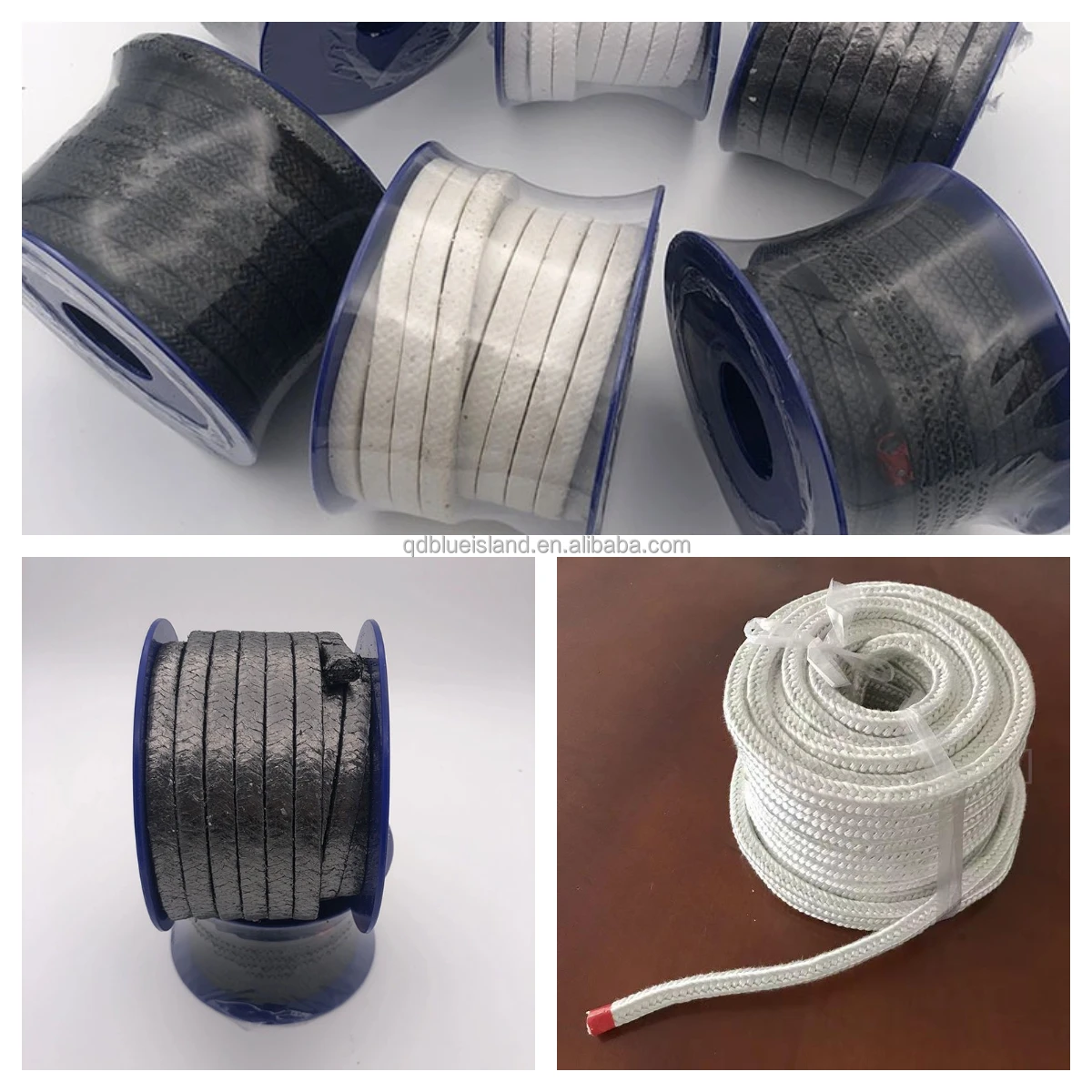

Friction Spinning or DREF Spinning is a textile technology that suitable for spinning coarse counts of yarns and technical corewrapped yarns.DREF yarns are bulky, with low tensile strength making them suitable for blankets and mop yarns, they can be spun from asbestos, carbon fibers and make filters was water systems.Yarns such as Rayon and Kevlar can be spun using this method.

Features

low tensile strength.Features Of Friction SpinningYarn properties:terry yarns; weft yarns. yarns for knitting; Application: low manufacturing cost; possibility for automation; no fast-moving parts .Advantages:up now no limited application possibilities;Features: delivery speed is independent from yarn count.Low energy expenses and low labor.Good uniformity,high production rates.

Product Paramenters

|

No. |

Specification |

Number |

|

1 |

machine name |

Friction spinning machine |

|

2 |

Spindle |

6 head |

|

3 |

motor control |

yes |

|

4 |

suitable fiber |

Cotton, man-made fiber, aramid fiber, hemp and recycled cotton etc |

|

5 |

dust cage diameter |

Φ83mm , length 220mm |

|

6 |

Combing roller diameter |

Φ178mm |

|

7 |

Bobbin size |

78mmX235mm (Cylindrical type ) |

|

8 |

Full bobbin weight |

Max 9 kg |

|

9 |

Spinning speed |

Max 250rpm |

|

10 |

Yarn count |

0-5 S |

.jpg)

.jpg)

.jpg)

.jpg)